TYPE-C Conductive FIBC Bulk Bag Used for Transporting Flammable Powder

Conductive ton bulk bags are commonly used for storing and transporting items that are sensitive to static electricity, such as powders, granular chemicals, dust, etc. Through its conductivity, it can safely handle these flammable materials, reducing the risk of fire and explosion. Its main uses include:

Preventing static electricity accumulation: Conductive ton bags can effectively prevent the accumulation and discharge of static electricity, thereby reducing the damage of static electricity to items. In some industrial fields, such as chemical, petroleum, powder, etc., static electricity may cause fires or explosions. The use of conductive ton bags can reduce this risk

Storage and transportation of flammable materials: Conductive ton bags are widely used for storing and transporting flammable materials, such as protecting static sensitive products. Some products are very sensitive to static electricity, such as electronic components, semiconductor devices, etc. Conductive ton bags can provide electrostatic shielding to prevent damage to these sensitive products from static electricity.

Specification

|

PRODUCT DETAILS

|

|||

|

PRODUCT NAME

|

FIBC Flexible Intermediate Bulk Containers

|

||

|

PRODUCT MATERIAL

|

100% virgin pp

|

||

|

PRODUCT STANDARD

|

Various specifications ,can be customized according to customer's requirements

|

||

|

PRODUCT COLOR

|

Orange, white, black, yellow, beige, or can be customized according to customer's requirements

|

||

|

APPLICATION AND SERVICE INDUSTRIES

|

• Chemical Manufacturers

• Quarries and Line Producers • Fiberglass Manufacturers • All Industrial Applications • Plastic Extrusion • Food Manufacturers (starch, flour, etc.) • Agriculture Markets (fertilizer, sod, feed mills) |

||

|

SAFETY FACTO

|

3:1/ 5:1/ 6:1 or customized

|

||

|

LOAD CAPACITY

|

500-3000kg

|

||

|

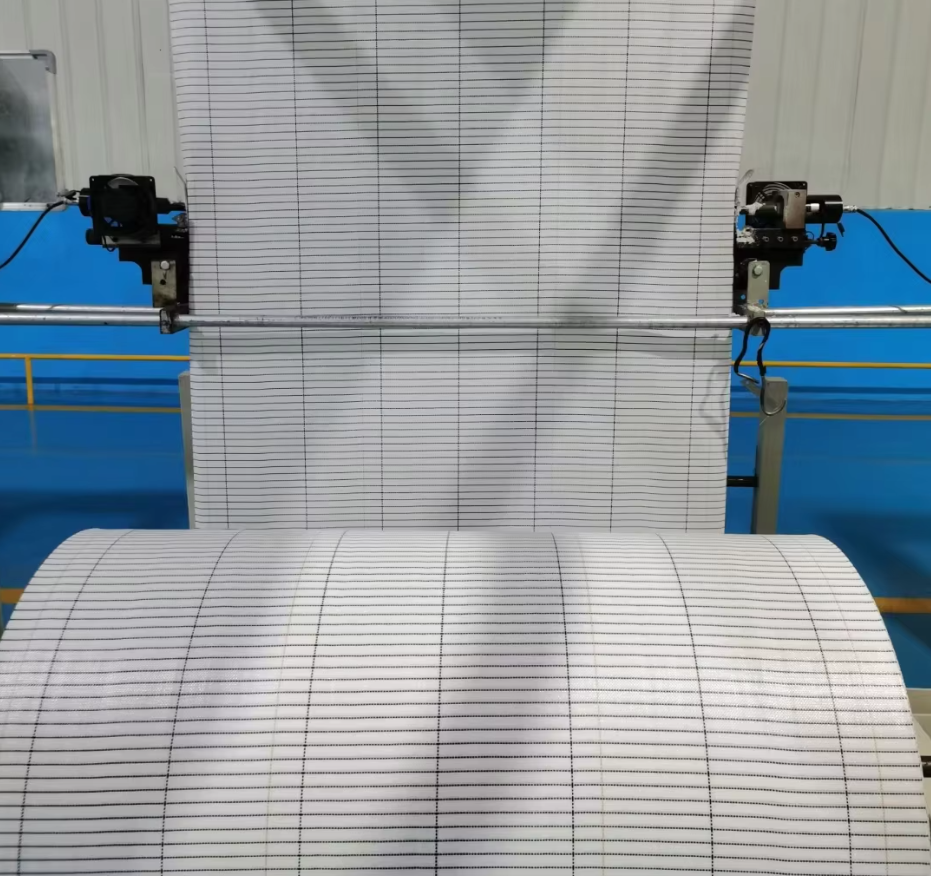

POLYPROPYLENE FABRIC TYPES

|

•Type A (Standard)

•Type B (Anti-Static) •Type C (Conductive) •Type D (Static Dissipative) |

||

|

TOP DESIGNS

|

•Cone Top

•Standard Fill Spout Top •Full Opening Duffel Top •Protective Top Cover |

||

|

DISCHARGE DESIGNS

|

•Concentric Discharge Spout

•Cone Bottom •Standard Discharge Spout, with protective cover •Double Bottom •Flat Bottom •Full Open Dump •Remote Open Discharge •Sling Bottom |

||

|

LIFT LOOP DESIGNS

|

•Cargo Straps

•Long Straps •Sleeve-Hemmed •Spread Strap •Standard Lift Loops •Stevedore Straps |

||

|

CLOSURE OPTIONS

|

•Drawstring

•Heavy-Duty Cord Lock •Hoop & Loop •Plastic Tie •Standard Cord Lock •Web Tie •Wire Tie •Zipper |

||

|

FIBC STYLES

|

•Baffle

•Four-panel •Tubular •U-Panel |

||

|

SPECIAL BAG CONSTRUCTION OPTIONS

|

•Certifications

•Clean Level/Food Grade Packaging •Clean Seal Cutting •Reinforcement Around the Top •Sift/Moisture Resistant •Colored Fabrics and Lift Loops •Custom Printing Available |

||

|

TESTING CAPABILITIES AND OPTIONS

|

Our principle plants all have internal test facilities that can perform all standard testing to meet industry standards. We perform routine lot testing of all production runs to ensure that the bags meet the standard safe working load ratios as established by the international accepted standards for FIBC’s.

|

||

Safe Use:

1. Used for transporting flammable powder.

2. When there is flammable solvent or gas around the container bag.

3. Used in filling and unloading environments with minimum ignition coefficient less than 3mJ