What's Two Loop Bulk Container Bag?

In the field of bulk packaging, flexible intermediate bulk containers (FIBC) (also known as bulk bags) have been widely used. The fibc with lifting rings will be called Two Loop Bulk Container Bag.

Importance: Why choose this type of bulk bag?

The reason that the customer choose this type bulk bag is it is a cost effective bulk-handling solution for transporting, storing and protecting different types of bulk products.

Part 1: Features of Two Loop Bulk Container Bag

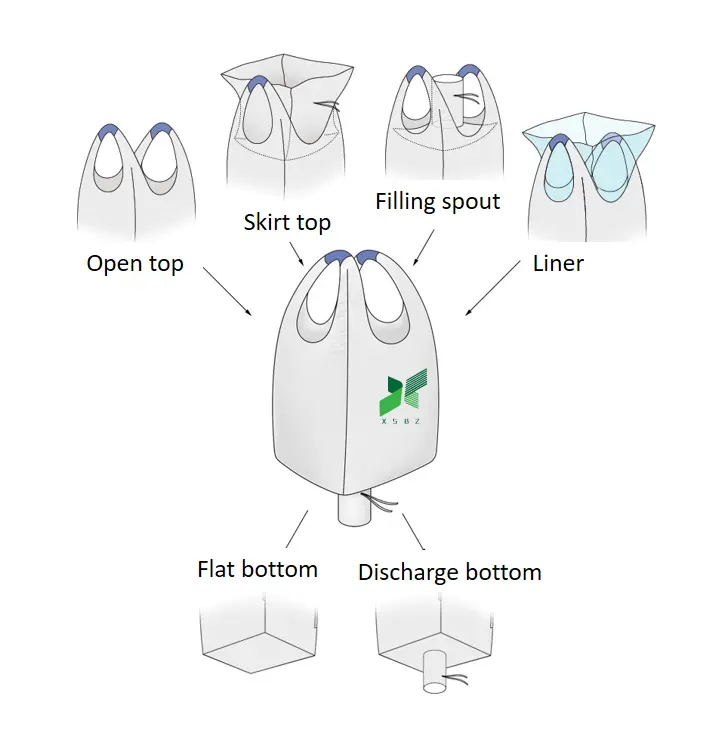

Provided in many designs, i.e. with filling and discharge spout, coated bags without liner, tray base bags, dangerous goods bags, fin liner base, etc.

1.1Design and structure

- Advantages of two loop design

high flexibility and improved logistics.

Two a lifting loop, giving it a higher tensile strength

- Material selection

Outer bag made of UV-protected polypropylene fabric and inner liner made of polyethylene film.

1.2 Application Fields

-Logistics and Transportation

-Architecture and Building Materials

-Agriculture and Food Industry

Part 2:Choose the appropriate Two Loop Bulk Container Bag

2.1 Size and Capacity

-How to choose the appropriate size based on demand?

We can make the personal cusomized big bag for our customers .

Big bags can be made for loads from 400 kg up to 3,000 kg. Fabric weights from 90 up to 200 g/m²

And we can provide available in different sizes/volumes from 400 liter up to 2,000 litres,it depends on the customer' request.

- Material selection

Outer bag made of UV-protected polypropylene fabric and inner liner made of polyethylene film.

2.2 Quality Standards

-Certification and standards (such as ISO)

ISO 21898: 2024 / EN ISO 21898: 2005,GB/T 10454-2000

Part 3:Part Three: Usage and Maintenance

3.1 Correct loading and unloading techniques

The material should be evenly loaded to avoid concentration in one place and prevent uneven stress on the ton bags.

Pay attention to the particle size and flow ability of the material to prevent blockage of the ton bag discharge port.

Do not exceed the maximum carrying capacity of the ton bag.

Suitable unloading equipment can be used to assist in unloading, ensuring clean unloading.

3.2 Cleaning and Storage Suggestions

After unloading the ton bags, there may be some residual materials inside the bags that need to be cleaned in a timely manner. You can gently wipe with water or detergent to remove stains and dust, and then let it air dry naturally in the sun.

When storing ton bags, it is necessary to have a warehouse without direct sunlight and avoid humid environments. At the same time, ton bags need to be stacked flat to avoid being squeezed by sharp object.

Part 4: Market Trends and Future Prospects

4.1 The rise of eco-friendly materials

4.2 Changes in Market Demand

With the continuous development of the packaging field, the market is also constantly changing, and container bags are always at the forefront of innovation, ensuring safe and efficient transportation and storage of goods.

Conclusion

-Summarize the advantages of Two Loop Bulk Container Bags

Two Loop Bulk Container Bag give high flexibility and improved logistics.

The bag itself extends into a lifting loop, giving it a higher tensile strength

A safe working load of 400-2000 kg

It can be customized as per customer’s requirements

Encourage readers to consider these factors when making choices

When choosing to purchase Two Loop Bulk Container Bags, we hope everyone can consider these factors and choose products that are suitable for themselves.

Post time: Oct-23-2024