Are you searching for a reliable and economical way to handle and transport bulk materials? This article delves into the world of two loop FIBC bags, a popular packaging solution known for its efficiency and cost-effectiveness. We'll explore why these loop fibc bags are a smart choice for various industries, offering a comprehensive understanding of their benefits and applications. Discover how these bulk packaging options can streamline your operations and save you money.

1. What are Two Loop FIBC Bags and Why Are They Gaining Popularity?

Two loop FIBC bags, also known as two loop bulk bags or single loop (when the two loops merge at the top), are a type of flexible intermediate bulk container used for storing and transporting various dry, flowable products. Unlike their four-loop counterparts, these fibcs feature either two distinct lifting loops or a single continuous loop that extends into two lifting points. This design simplifies handling, especially during loading and unloading processes using a forklift with a single hook.

Their increasing popularity stems from several advantages. Firstly, they often present a more cost-effective option compared to 4 loop fibc bags, as they require less material and a simpler manufacturing process. Secondly, their design allows for quicker handling in certain applications, making them an efficient packaging choice. As businesses like yours, Mark, are always seeking ways to optimize costs without compromising on quality, two loop fibc bags offer a compelling solution. We, as a bulk bags manufacturer with 7 production lines in China, have witnessed this growing preference firsthand, particularly from our clients in the USA, North America, Europe, and Australia.

2. Two Loop vs. Four Loop FIBC Bags: Which Bulk Bag is Right for You?

The choice between two loop fibc bags and four loop bags largely depends on your specific material handling needs and infrastructure. Four loop fibc bags are the more traditional and versatile option. They feature four distinct lifting loops at each corner, providing balanced lifting and stability, making them suitable for a wide range of lifting equipment. They are generally preferred when using a two-hook crane or when extra stability is required, especially with heavier loads.

Two loop fibc bags, on the other hand, are designed for single-point lifting. The loop design, whether two separate loops or a single one, allows for quick and easy engagement with a single hook forklift. This can significantly speed up loading and unloading operations, particularly when handling lighter to medium-weight materials. For companies like yours, Mark, that prioritize speed and efficiency in your transport operations, loop bags can be a valuable asset. While 4 loop bulk bags offer more versatility in lifting methods, two loop bags excel in streamlined, single-hook environments. Think about the type of equipment you primarily use and the speed you need to maintain in your transport processes.

3. What Industries Benefit Most from Using Two Loop FIBC Bags?

Several industries find two loop fibc bags to be an ideal packaging solution. The agricultural sector frequently utilizes them for handling grains, seeds, and fertilizer. The ease of loading and unloading with a forklift makes them practical for farm operations. Similarly, companies dealing with powdered or granular materials, such as certain chemical manufacturers, also benefit from their efficient handling.

Logistics and shipping companies appreciate the streamlined process when using two loop fibc bags, especially for goods being moved within warehouses or distribution centers where single-hook lifting is common. Even some segments of the mining industry might find them suitable for lighter materials. Considering your business model, Mark, where you supply big bags and liners to agriculture companies, mining companies, and chemical manufacturers, understanding the advantages of loop fibc bags will allow you to better cater to their specific requirements. The bags are widely accepted and utilized across these sectors due to their balance of cost and efficiency.

4. What Key Features Make Two Loop FIBC Bags an Efficient Packaging Solution?

Several features contribute to the efficiency of two loop fibc bags. The primary advantage lies in their simplified lifting loop design, facilitating faster engagement with single-hook lifting equipment. This reduces handling time and increases operational throughput. The bags are designed for straightforward filling and discharge, often featuring open tops or spouts for easy access.

Furthermore, the strength and makes these fibcs durable for repeated use in some applications, though they are often designed for single-trip use. The woven polypropylene construction provides a robust barrier against tearing and moisture. Customization options, such as the addition of an inner liner, further enhance their utility for containing fine powders or materials requiring extra protection. For Mark Thompson, considering the emphasis on efficient operations for his clients, highlighting these features will resonate with his purchasing preferences.

5. How to Choose the Right Two Loop FIBC Bag for Your Specific Needs?

Selecting the appropriate two loop fibc bag involves considering several factors. Firstly, assess the weight and density of the material you intend to package. This will determine the necessary bulk bag's safe working load (SWL). Next, evaluate the filling and discharge methods required. Do you need an open top, a filling spout, or a discharge spout?

The dimensions of the bag are also crucial, ensuring it fits your store space and transportation methods. Consider whether you require a liner for added protection against moisture or contamination. Finally, factor in any specific regulatory requirements or safety standards relevant to your industry and the material being packaged. Understanding these needs allows you to choose the right loop fibc bags that meet your operational and safety requirements. As a knowledgeable buyer, Mark, you'll appreciate this detailed consideration of your client's diverse needs.

6. What are the Key Benefits of Two Loop FIBC Bags for Bulk Packaging?

Two loop fibc bags offer a range of significant benefits for bulk packaging needs. Their cost-effective nature, primarily due to simpler construction and less material usage, makes them an attractive option for businesses conscious of their bottom line. The ease and speed of handling with single-hook equipment lead to increased efficiency in material handling.

These bags are ideal for lighter to medium-weight loads, offering a balance between strength and ease of manipulation. Their adaptability for various dry, flowable materials makes them versatile. Moreover, when compared to smaller packaging formats, bulk bags significantly reduce handling time and labor costs. For your customers, Mark, these benefits translate directly to improved profitability and streamlined operations.

7. Looking for a Reliable Loop FIBC Bags Supplier? What to Consider?

Finding a trustworthy loop fibc bags supplier is crucial for ensuring the quality and reliability of your packaging. Look for a manufacturer with a proven track record and positive client testimonials. Certifications like ISO standards are important indicators of quality management. As you know, Mark, certifications such as ISO standards address one of your key concerns when purchasing.

Evaluate the supplier's production capacity and lead times to ensure they can meet your demand and avoid shipment delays, another of your pain points. Clear communication and responsiveness from the sales representatives are essential for a smooth purchasing process – addressing your concern about inefficient communication. Don't hesitate to inquire about their quality inspection processes and payment methods. As a factory with 7 production lines, we at XS Bulk Bag prioritize transparency and open communication with our clients. We understand the importance of reliable logistics and secure payment methods. Consider visiting exhibitions to meet potential suppliers face-to-face, a method you yourself utilize to find suppliers.

8. Are There Different Types of Two Loop FIBC Bags Available?

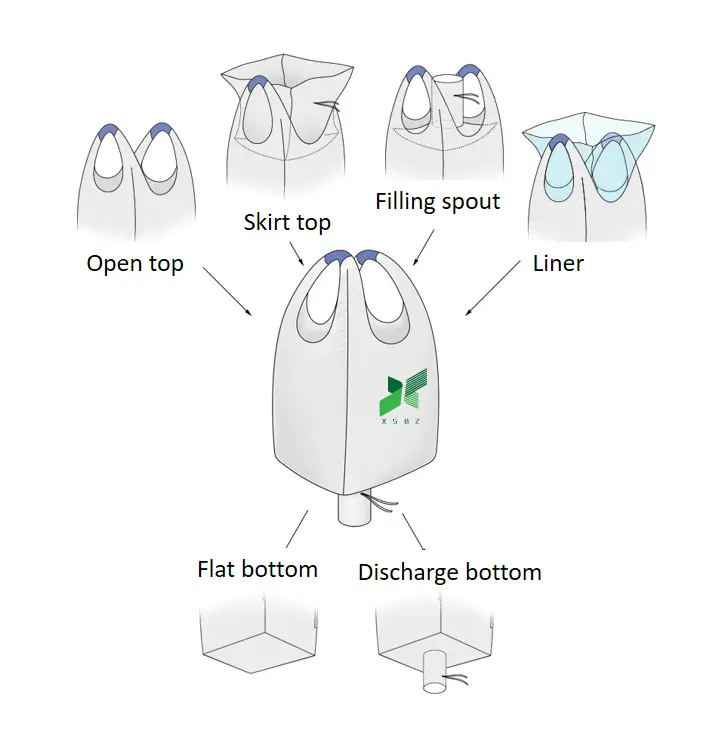

Yes, while the fundamental design of two loop fibc bags remains consistent, variations exist to suit different applications. Some feature different top and bottom constructions, such as open tops, filling spouts, discharge spouts, or flat bottoms. The lifting loop design itself can vary, with some having two distinct loops and others a single continuous loop.

The body fabric weight and construction can also differ depending on the intended load and material. Options with liners are available for added protection. Understanding these variations allows you to select the specific type of loop fibc bulk bags that perfectly matches your bulk packaging requirements. For example, you might consider PP Woven Container For Dangerous Goods Type C Jumbo anti Static Bulk Bag for specific hazardous materials.

9. What are the Material and Construction Aspects of Loop FIBC Bulk Bags?

The primary material used in loop fibc bulk bags is polypropylene, a thermoplastic polymer known for its higher breaking strength and durability. The bags are constructed from woven polypropylene fabrics, creating a strong and flexible structure. The weight and weave density of the fabric can be adjusted to meet specific load requirements.

The lifting loops are typically made from the same polypropylene material and are securely sewn onto the bag's body, often with reinforced stitching to ensure safe lifting. UV stabilizers are frequently added to the polypropylene to protect the bags from degradation when exposed to sunlight, extending their lifespan. This robust construction ensures the safe and reliable transportation and storage of bulk materials. Consider exploring our range of PP Woven PE Bulk Container Liners for additional options.

10. How Do Liners Enhance the Functionality of 2 Loop FIBC Bags?

Adding a liner to 2 loop fibc bags significantly enhances their functionality for certain applications. Liners, typically made of polyethylene (PE) film or other barrier materials, provide an extra layer of protection for the contents. They are particularly useful when packaging fine powders, preventing leakage and ensuring product integrity.

Liners also offer moisture protection, making the bags suitable for hygroscopic materials. For industries with strict hygiene requirements, such as food or pharmaceutical, food-grade liners maintain product purity. The inner liner is inserted into the fibc bag and can be either loose or attached. For businesses like Mark's, serving clients with diverse needs, offering big bag liners as part of your product range is essential. You might also consider Aluminum Film Bags for specific protective needs.

Key Things to Remember About Two Loop FIBC Bags:

- Cost-Effective: Often a more economical option compared to four-loop bags.

- Efficient Handling: Designed for quick and easy lifting with single-hook equipment.

- Suitable for Various Industries: Widely used in agriculture, chemicals, and logistics.

- Customizable: Available with different top/bottom designs and optional liners.

- Durable Construction: Typically made from woven polypropylene for strength.

- Liner Options: Enhance protection against moisture and leakage.

- Consider Your Needs: Choose based on material weight, handling methods, and specific requirements.

- Find a Reliable Supplier: Look for experience, certifications, and good communication.

- Prioritize Quality: Ensure the bags meet necessary safety standards.

By understanding the benefits and applications of two loop fibc bags, you can make informed decisions to optimize your bulk packaging solutions and improve your operational efficiency.

Post time: Dec-26-2024