In the current logistics and packaging field, the storage and transportation of bulk materials has always been a key issue faced by enterprises. How to solve the problems of bulk cargo transportation and moisture prevention? At this point, FIBC liners entered the public's field of vision. This reusable bag provides a new solution for the storage and transportation of bulk materials. So how does FIBC liners enhance bulk packaging solutions?

Firstly, understanding the basic components of FIBC lines

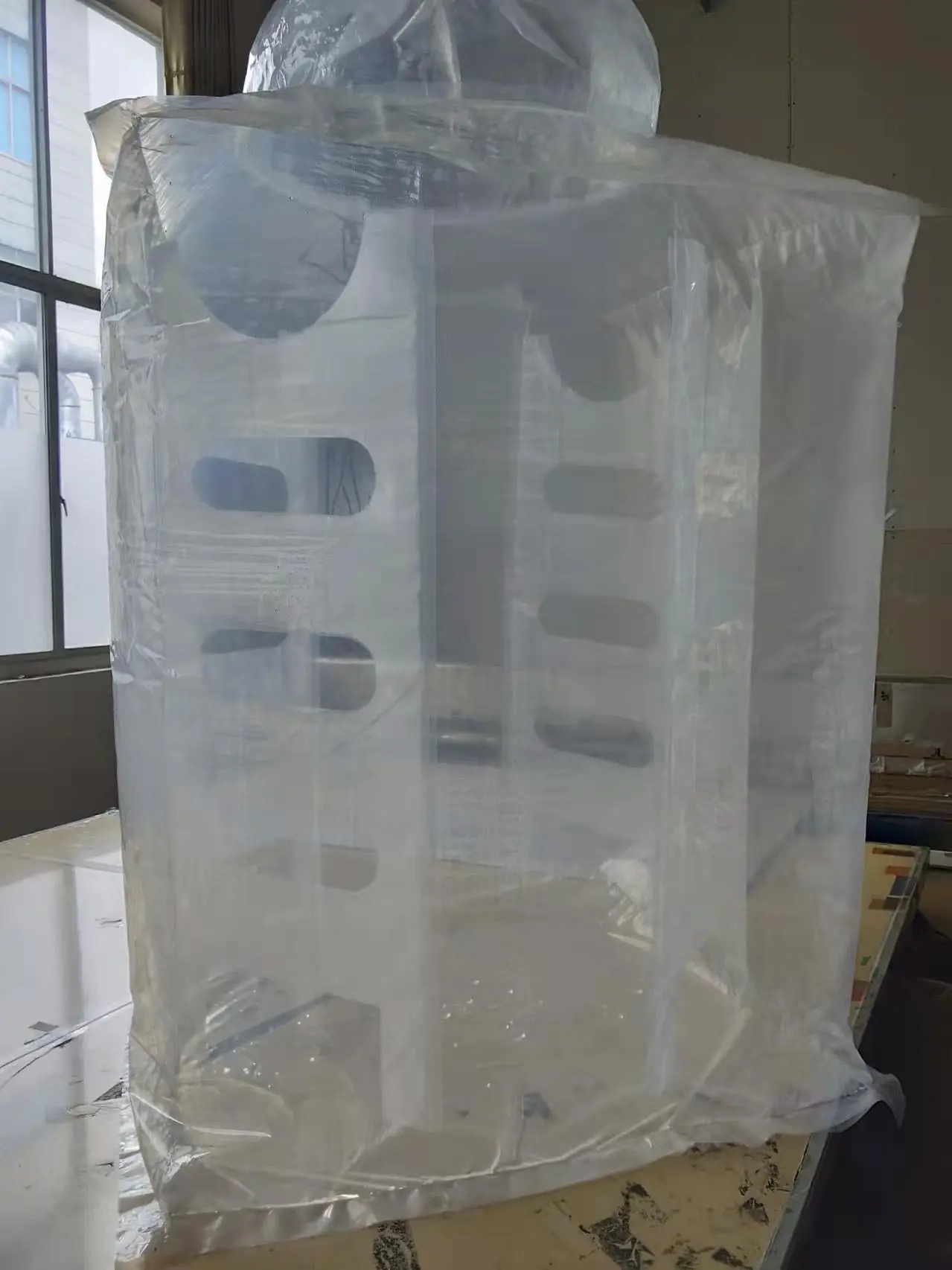

These types of bags are usually made of wear-resistant, tear resistant polypropylene or other synthetic materials, and are mostly used to carry large amounts of powder and particles. They have excellent moisture, dust, and UV resistance, which enhances their applicability in complex environments.

Secondly, improve and optimize the design of FIBC liners

According to the characteristics of the load-bearing material, bulk bag liners of different shapes and sizes can be customized to meet different loading requirements. For example, increasing the design of straps and discharge ports can facilitate the loading, unloading, and emptying of materials. At the same time, we also need to pay attention to the coordination of auxiliary tools such as forklifts, pallets, and cranes. By using appropriate lifting tools, pallets, and other handling facilities, the advantages of FIBC liners can be maximized.

Thirdly, understand the advantages of FIBC liners.

FIBC liner bags can be reused multiple times, greatly reducing waste generation and reducing environmental pressure. Meanwhile, its materials are recyclable, further embodying the concept of green environmental protection. Some FIBC liners also have superior barrier properties. They can effectively prevent moisture or contamination of goods and maintain their original quality. Different bulk materials have different requirements for the material of the bag. For example, for highly corrosive chemicals, whether liquid or particle, we need to choose FIBC liners that are resistant to chemical corrosion; For food grade materials, FIBC liners are required to comply with food grade hygiene standards.

Implement standardized operating procedures for FIBC liners

Proper loading, unloading, and storage operations can not only extend the service life of FIBC liners, but also prevent material contamination and loss.

Finally, let's talk about the prices of FIBC liners. Although it has many advantages, the price of FIBC lining bags is still acceptable. Our container liner bag enterprise optimizes production processes and large-scale production to make high-quality liner bags available to the market at reasonable prices.

As part of the bulk packaging solution, the reinforcement effect of FIBC lines cannot be ignored. Through precise material selection, scientific design, correct use of auxiliary equipment, and standardized operating procedures, we can fully utilize the advantages of FIBC liners to improve the efficiency, safety, and economy of the entire packaging scheme, better serving the needs of modern logistics.

The fifth is to pay more attention to environmental factors. With the global emphasis on sustainable development, whether FIBC liners can be recycled has become an important consideration. The use of recyclable materials not only reduces environmental burden, but also lowers long-term usage costs.

Post time: Mar-21-2024