Polypropylene ton bags, which means large packaging bags made mainly of polypropylene (PP) as the main raw material, are commonly used to load large amounts of bulk materials. This type of packaging bag has been widely used in many industrial fields due to its unique durability and practicality. Here, we will study exploring types of products typically packaged in PP Jumbo Bags the packaging types covered by polypropylene bulk bags and learn relevant knowledge together.

Polypropylene is widely popular due to its excellent physical properties, chemical stability, and cost-effectiveness.As a transportation and storage container for bulk materials, Jumbo Bags are designed to carry cargo weighing from 0.5 to 3 tons. Due to its reusable and environmentally friendly characteristics, polypropylene jumbo bags also have significant advantages in terms of environmental protection and economy.

The application of big bags in various fields of our lives, the two main fields are agriculture and chemical industry. In the agricultural field, Jumbo Bags are widely used to package various types of grains, such as wheat, rice, corn, and various beans. The common feature of these products is that they require long-term storage and can maintain their quality over a large temperature range. Therefore, PP ton bags provide an excellent solution in terms of moisture resistance, insect resistance, and ease of handling.

The chemical industry is another important application field. In this industry, PP Jumbo Bags are often used to load powdered, granular, or block like chemical substances. For example, plastic particles, fertilizers, salt, carbon black, etc. For such products, ton bags not only provide reliable chemical stability, but also ensure safety and cleanliness during transportation.

In addition to the industries mentioned above,PP Jumbo Bags are also used in industries such as construction, mining, metallurgy, and food. For example, in the mining industry, it is used to load mineral sand, metal powder, etc; In the food industry, it is used to pack food ingredients such as sugar, salt, and seasonings.

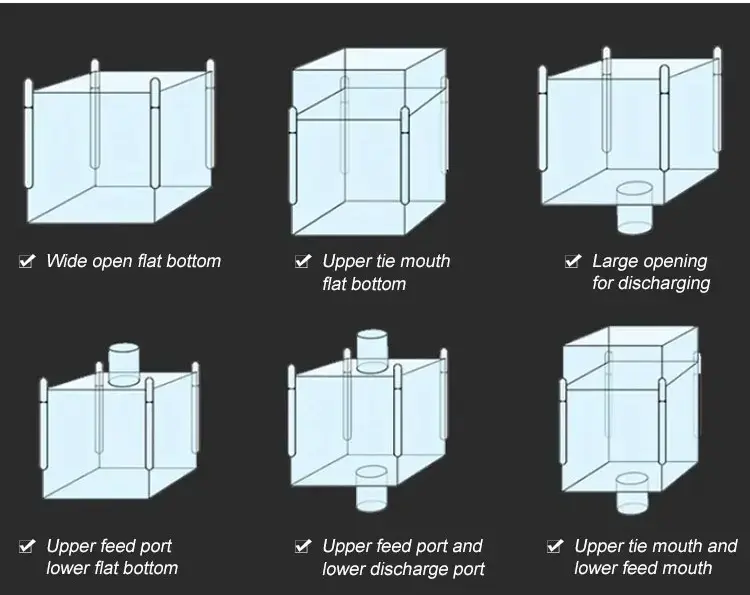

The design of pp big bags usually takes into account different loading requirements, and they may be equipped with lifting straps, feed and discharge ports, and other auxiliary components to adapt to different handling equipment and loading and unloading requirements. In addition, to ensure the safety of goods, clear safety signs such as maximum load capacity and stacking restrictions will also be marked on the bulk bags.

From a structural design perspective, there are various types of PP Jumbo Bags, including open type, closed type, and covered type. The open ton bag is convenient for filling and emptying the contents, while the closed design helps to keep the contents dry and clean. The ton bag with a lid can be reused and is easy to seal for storage.

According to the different lifting methods, jumbo bags can be divided into models such as corner lifting, side lifting, and top lifting. The four corner hanging ton bag is particularly suitable for the transportation of heavy goods due to its stable structure, while the side and top lifting provide more flexibility in handling.

Next, considering different usage scenarios and needs, polypropylene ton bags may also undergo special processing treatments, such as anti-static treatment, UV protection treatment, anti-corrosion treatment, etc. These special treatments enable ton bags to better protect the contents under specific conditions and extend their service life.

In order to meet the market's requirements for environmental protection, recyclable PP bulk bags are also receiving increasing attention. This type of ton bag was designed with the possibility of recycling in mind, which not only reduces the pressure on the environment but also lowers the user's usage cost.

PP Jumbo bags play a very important part in modern industrial and agricultural production. Understanding their application types can not only help us better understand this packaging tool, but also make us realize the importance of reasonable use and recycling. In the future, polypropylene ton bags will continue to provide convenience for our production activities, and we should also continue to pay more attention to their impact on the environment, promoting the industry towards a more green and sustainable development path.

Post time: Apr-08-2024