Are you looking for a reliable and cost-effective way to protect your bulk cargo during shipment? This article explores the world of dry bulk container liners, a crucial packaging solution for safely and efficiently transporting various dry bulk commodities. We'll delve into the properties of dry bulk liners, their advantages, and why they are an increasingly popular choice for businesses involved in bulk shipping. Discover how these shipping container liners can ensure cargo protection, maintain hygiene, and streamline your logistics.

1. What are Dry Bulk Container Liners and Why Are They Essential for Cargo Protection?

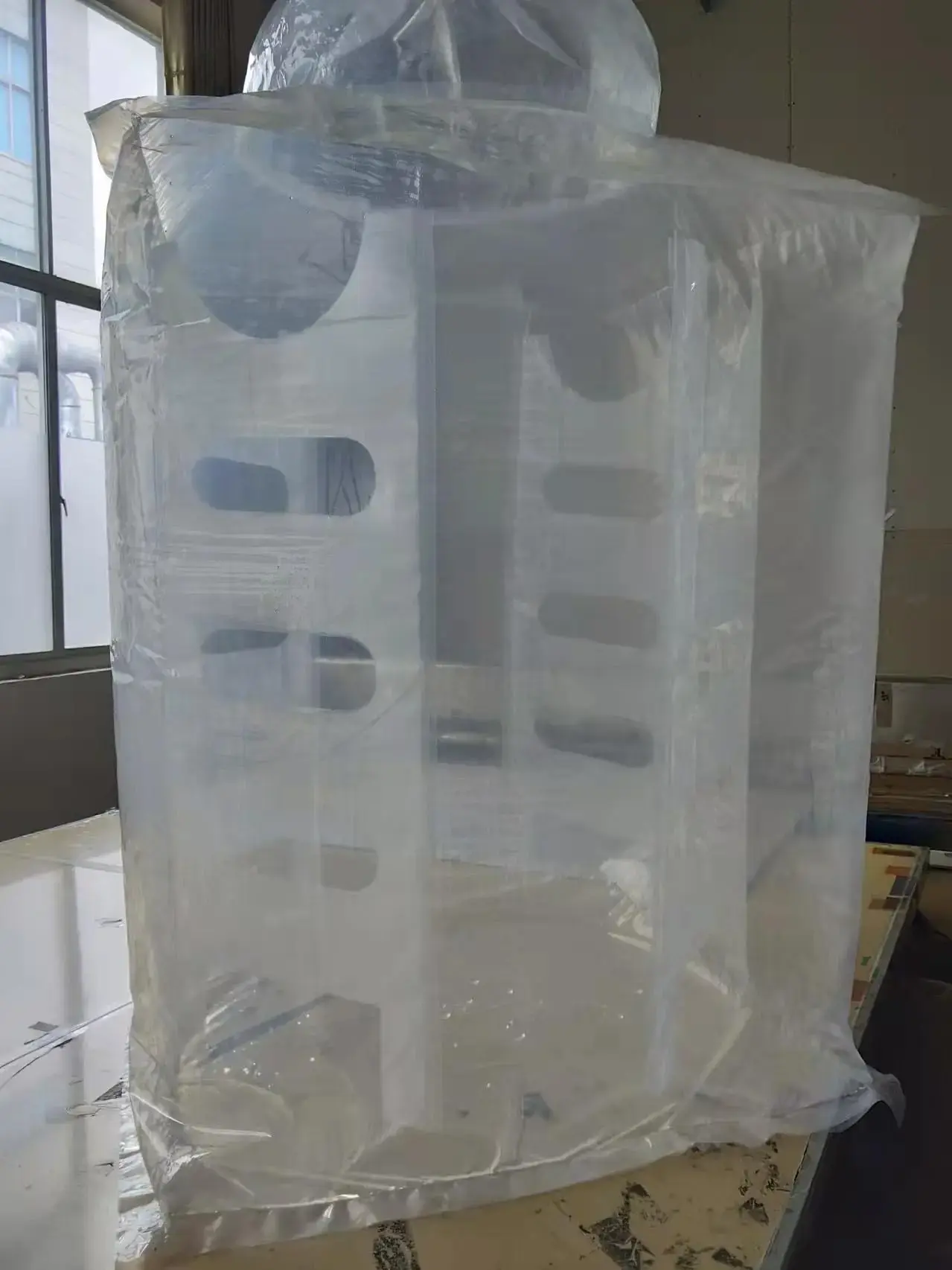

Dry bulk container liners, also known as bulk container liners or simply container liners, are large bag-like structures designed to fit inside standard shipping containers. These liners are designed to create a clean and protective environment for transporting dry bulk goods, such as grains, powders, and granules. Imagine a giant, customized bag fitting snugly within your container, safeguarding its contents throughout the journey.

The primary reason for their essential nature is cargo protection. Container liners act as a barrier between the cargo and the container walls, preventing contamination from previous cargo, moisture, or other external elements. This is crucial for maintaining the integrity and quality of bulk cargo, ensuring it arrives at its destination in the same condition it was shipped. Without this protection, bulk materials can be easily spoiled or damaged during transport.

2. How Do Container Liners Differ from Traditional Bulk Packaging Methods?

Traditional bulk packaging often involves loose loading of cargo directly into the container or using smaller, individual bags. While seemingly straightforward, these packaging methods present several challenges that container liners effectively address. Loose loading exposes the dry bulk cargo directly to the container walls and any residual contaminants. Using numerous smaller bags increases handling time, labor costs, and the risk of damage during loading and unloading.

Container liners offer a significant improvement by creating a sealed environment within the container. This packaging solution eliminates the need for additional packaging materials like pallets or smaller bags, reducing waste and streamlining the supply chain. The liners allow for faster loading and unloading processes, as the entire bulk of the cargo can be handled as one unit. This shift from manual handling of individual units to a more unified approach brings substantial efficiency gains.

3. What are the Key Properties of Dry Bulk Container Liners That Ensure Cargo Integrity?

Several key properties of dry bulk container liners contribute to their effectiveness in protecting cargo. Firstly, they are typically liners made from strong, tear-resistant materials like polypropylene or polyethylene. This ensures the liner can withstand the rigors of transport.

Secondly, many container liners are moisture-resistant, safeguarding dry bulk cargo from humidity and potential water damage. Some liners come with specialized barrier layers that further enhance protection against moisture and gases. Thirdly, the seams of high-quality liners are carefully sealed to prevent leaks and ensure the cargo remains contained. These properties collectively ensure the quality of bulk cargo throughout its journey.

4. What Types of Cargo Benefit Most from Using Dry Bulk Container Liners?

A wide range of dry bulk cargo benefits from the protection offered by container liners. Agricultural products like grains (wheat, rice, soybeans), seeds, and pulses are commonly transported using these liners. The liners act as a crucial barrier against moisture and pests, ensuring the cargo arrives in good condition.

Food-grade liners are essential for maintaining the hygiene of foodstuffs. Industrial materials such as resins, powders, and granules also benefit significantly. The liners reduce the risk of contamination and product loss during transport. Even certain mineral products and fertilizers are transported using container liners to prevent spillage and environmental issues. If your business involves the transport of such bulk goods, container liners offer a superior packaging solution.

5. What are the Advantages of Using Container Liners for Your Shipments?

The advantages of using container liners are numerous. Enhanced cargo protection is paramount, minimizing damage and loss during shipment. The liners act as a protective layer, shielding the cargo from external elements and the condition of the container itself. This translates to fewer rejected shipments and happier customers.

Improved hygiene is another significant advantage, especially for food and agricultural products. Container liners create a clean environment, preventing contamination and ensuring the quality of bulk cargo. Furthermore, using container liners can lead to significant cost savings by reducing the need for additional cleaning of shipping containers after each use. The speed and ease of loading and unloading also contribute to operational efficiency.

6. How Do Container Liners Contribute to Cost Savings and Efficiency in Logistics?

Container liners contribute to cost savings in several ways. By protect bulk goods effectively, they minimize product damage and loss during transport, reducing financial write-offs. The streamlined loading and unloading processes save time and labor costs. Because the liners allow for the transport of bulk cargo without the need for individual packaging, expenses related to bags, pallets, and other packaging materials are significantly reduced.

Furthermore, container liners allow for the use of standard shipping containers for dry bulk cargo, eliminating the need for specialized and more expensive equipment. This cost-effectiveness extends to cleaning as well; liners reduce the need for intensive cleaning of the container after each shipment, saving both time and resources. For businesses focused on efficient logistics, the benefits are clear.

7. What Materials are Container Liners Made From and Why is Material Choice Important?

Container liners are typically made from polyethylene (PE) or polypropylene (PP) fabrics. Polyethylene is a cost-effective option offering good moisture resistance, commonly used for transporting non-hazardous goods. Polypropylene, on the other hand, offers higher breaking strength and tear resistance, making it suitable for heavier or more abrasive bulk cargo.

The choice of liner material is critical as it directly impacts the cargo protection capabilities. For instance, transporting food requires liners that meet specific food-grade standards. For dry bulk cargo susceptible to moisture, liners made with specialized moisture barrier layers are essential. Sometimes, liners come with an inner coating of polyethylene laminated to a woven polypropylene outer layer for enhanced strength and protection. Understanding the properties of dry bulk being transported dictates the most appropriate liner material.

8. How are Dry Bulk Container Liners Installed and What Makes Installation Efficient?

The installation of dry bulk container liners is designed to be relatively straightforward and efficient. Typically, the liner is unfolded and suspended within the container, often using straps or hooks that attach to the container's lashing points. One person can usually install a container liner within a short timeframe.

The efficiency of installation is a significant advantage, minimizing downtime during the loading and unloading process. The liners are designed to fit inside standard shipping containers snugly, maximizing the use of space and preventing wasted space. Once the cargo is loaded, the top of the liner is sealed, creating a secure and protected environment for transport. This ease of installation is a key factor in the cost-effectiveness of using container liners.

9. Are There Different Types of Container Liners Available to Suit Various Cargo Needs?

Yes, there are various types of container liners available, each tailored to specific cargo requirements. Some common variations include:

- Box Liners: These are the most common type, forming a complete "box" inside the container.

- Form-Fit Liners: These liners are custom-made to precisely fit the dimensions of the container, minimizing movement during transport.

- Ventilated Liners: These feature breathable panels to allow for air circulation, important for certain agricultural products.

- Bulkhead Liners: These are used when only partial lining is required.

- Liquid Liners (Flexitanks): Although not strictly for dry bulk, these are worth mentioning as they serve a similar purpose for liquids.

Understanding the different types ensures you can select the best container liners for your specific bulk cargo transportation needs. We, as a manufacturer, offer a range of bulk container liners to meet the diverse needs of our clients. For example, our 20FT/40hq PP Woven Inner Dry Bulk Container Liner is a popular choice for many applications.

10. Choosing the Right Container Liner: What Factors Should You Consider for Optimal Cargo Protection?

Selecting the right container liner is crucial for ensuring optimal cargo protection. Key factors to consider include:

- Type of Cargo: The nature of your dry bulk cargo (e.g., density, moisture content, potential for abrasion) will dictate the necessary material and features of the liner.

- Transportation Distance and Conditions: Longer journeys or harsher environments may require more robust liners.

- Loading and Unloading Methods: Consider how the cargo will be loaded and discharged to ensure the liner design is compatible.

- Food Grade Requirements: If transporting food, ensure the liners meet relevant safety and hygiene standards.

- Cost Considerations: While cost-effective, different liner types have varying prices. Balance your budget with the required level of protection.

By carefully evaluating these factors, you can choose the container liner that provides the most effective and cost-effective choice for businesses looking to transport dry bulk. Considering our Food Grade Dry Bulk Container Liner For Soybeans might be relevant if your cargo falls under that category.

Key Things to Remember About Dry Bulk Container Liners:

- Essential for Cargo Protection: They act as a barrier against contamination and damage.

- Cost-Effective Solution: Reduce the need for additional packaging and cleaning.

- Improve Efficiency: Streamline loading and unloading processes.

- Maintain Hygiene: Crucial for food and agricultural bulk cargo.

- Various Types Available: Tailored to different cargo needs.

- Material Choice Matters: Polyethylene and polypropylene are common materials.

- Easy Installation: Minimizes downtime.

- Suitable for Diverse Cargo: From grains to industrial powders.

- Sustainable Packaging: Reduces waste compared to traditional methods.

- Contribute to Supply Chain Efficiency: Simplify handling and transport.

By understanding the benefits and considerations associated with container liners, you can make informed decisions to enhance your bulk shipping operations and ensure the safe and efficient delivery of your valuable cargo.

Post time: Jan-14-2025