Heavy Duty FIBC Bag for Construction Cement

Description

Big bags have developed rapidly in recent years due to their convenient loading, unloading, and transportation, resulting in significantly improved loading and unloading efficiency.

It has the advantages of moisture-proof, dust-proof, radiation resistant, sturdy and safe, and has sufficient strength in structure.

Specification

| Model | U panel bag, Cross corner loops bag, Circular bag, One loop bag. |

| Style | Tubular type, or square type. |

| Internal size (W x L x H) | Customized size, sample is available |

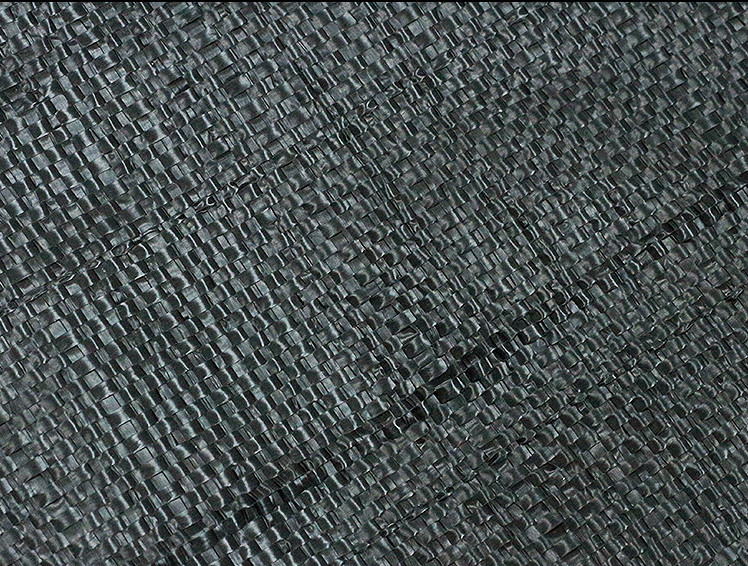

| Outer fabric | UV stabilized PP 125gsm,145gsm,150gsm,165gsm,185gsm, 195gsm, 205gsm, 225gsm |

| Color | beige,white or others such as black,blue,green,yellow |

| SWL | 500-2000kg at a 5:1 safety factor, or 3:1 |

| Lamination | uncoated or coated |

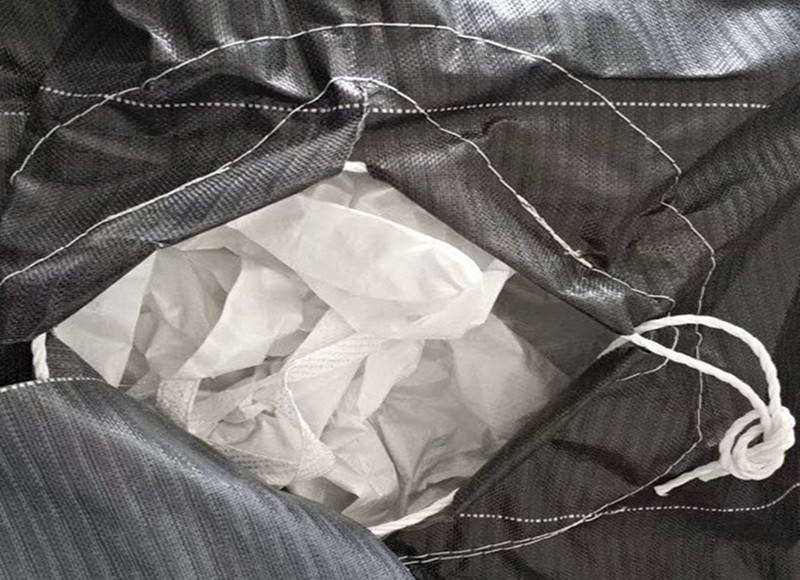

| Top style | filling spout of 35x50cm or full open or duffle (skirt) |

| Bottom | discharge spout of 45x50cm or flat close |

| Lifting/webbing | PP, 5-7 cm width, 25-30 cm height |

| PE Liner | available,50-100 microns |

Models

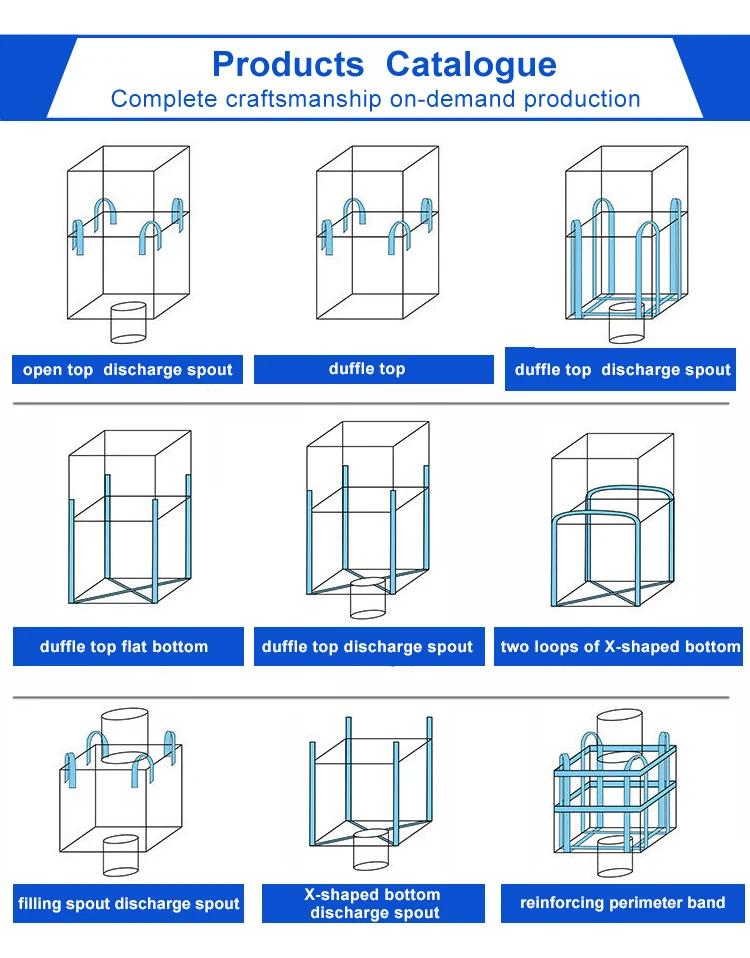

There are various types of FIBC ton bags and container bags on the market now, but they all have their commonalities, mainly divided into the following categories:

1. According to the shape of the bag, there are mainly four types: cylindrical, cubic, U-shaped, and rectangular.

2. 2. According to loading and unloading methods, there are mainly top lifting, bottom lifting, side lifting, forklift type, pallet type, etc.

3. Classified by discharge port: it can be divided into two types: with discharge port and without discharge port.

4. Classified by bag making materials: there are mainly coated fabrics, double warp base fabrics, interwoven fabrics, composite materials, and other container bags.

Application

Our ton bags are used in various fields, such as sand, steel plants, coal mines, warehousing, cable materials and so on .